|

|

Ultrasonic • Visual • Eddy Current • EMAT • Resonant Inspections

also - Laser Geometry Measurement & Parts Cleaning Systems

|

|

ULTRASONIC INSPECTION (UT) -

- Automated In-Line & Off-Line Plate UT

- Automated UT of Pipe, Bars, Billets, and Rails

- Wireless & Robotic UT of Longitudinal & Circumferential Pipes & Tanks

- UT of Friction Stir Welds

- Flaw Detectors

- Thickness Gages

- UT Reference, Resolution, & Calibration Blocks

- UT Area & Distance/Area Amplitude Blocks

- McDonnell Douglas UT Reference Standards, Boeing UT Angle Beam Block, Convex Surface Standards, Sizing Blocks, ASTM Standards,...

- Couplants

|

|

|

EDDY CURRENT INSPECTION (ET) -

- Automated In-Line or Off-Line, Non-Contact Detection of Hard Spots/Bruises in Plates using ET

- ET Test Blocks & Coupons

|

|

|

ELECTRO-MAGNETIC ACOUSTIC TRANSDUCTION (EMAT) - a type of Ultrasonic Inspection that generates the sound in the part under inspection instead of in the Transducer as with traditional UT.

- Non-Contact, EMAT Portable Gauge to determine Wall Thickness in Ferrous and Non-Ferrous materials to detect: Corrosion, Erosion, and characterization of mechcanical properties (hot spots)

- Non-Contact, In-Line EMAT Grain Size Monitoring

- Non-Contact, In-Line EMAT Wall Thickness Measurement

- Non-Contact, In-Line EMAT Scarfing Quality Inspection to maintain Weld line tolerances prior to cut-off

- EMAT of blooms coming directly off the continuous casting line to detect Liquid Core to ensure the correct position to cut the bloom. This avoids: liquid metal losses which lead to equipment damage, higher material scrap rates, and reduced lifespan of production lines

- Mechanized, Non-Contact EMAT for wall thickness of combustion engine cylinder sleeves

- Automated, Non-Contact EMAT of electronic components such as multilayer ceramic capacitors and ferrite components

|

|

|

RESONANT INSPECTION (RI) - the part Non-Destructively hits, or is hit by, a RAM Impactor (RAM) that causes a structural vibration / part resonance, just like the 'ringing of a bell'. Just as a Bell with a crack will produce a different sound, the Resonant Inspection (RI) System can determine: the presence of both internal and surface defects, material property differences, dimensional differences, wall thickness differences, and coating thickness differences. The resonance applied to the part allows for a computer aided, automated, Pass-Fail, Resonant Inspection (RI) of the entire part in one single, rapid test.

- Automated, Pass-Fail (RI) using a RAM Drop with Automated Sorting

- Automated, Pass-Fail (RI) using an automated RAM Conveyor with Automated Sorting

- Automated, Pass-Fail (RI) using an automated RAM Work Table

- Automated, Pass-Fail (RI) using a manual RAM Hammer

|

|

|

AUTOMATED LASER GEOMETRY MEASUREMENT SYSTEM - for plates, sheets, strips, and slabs of both ferrous and non-ferrous metals.

|

|

|

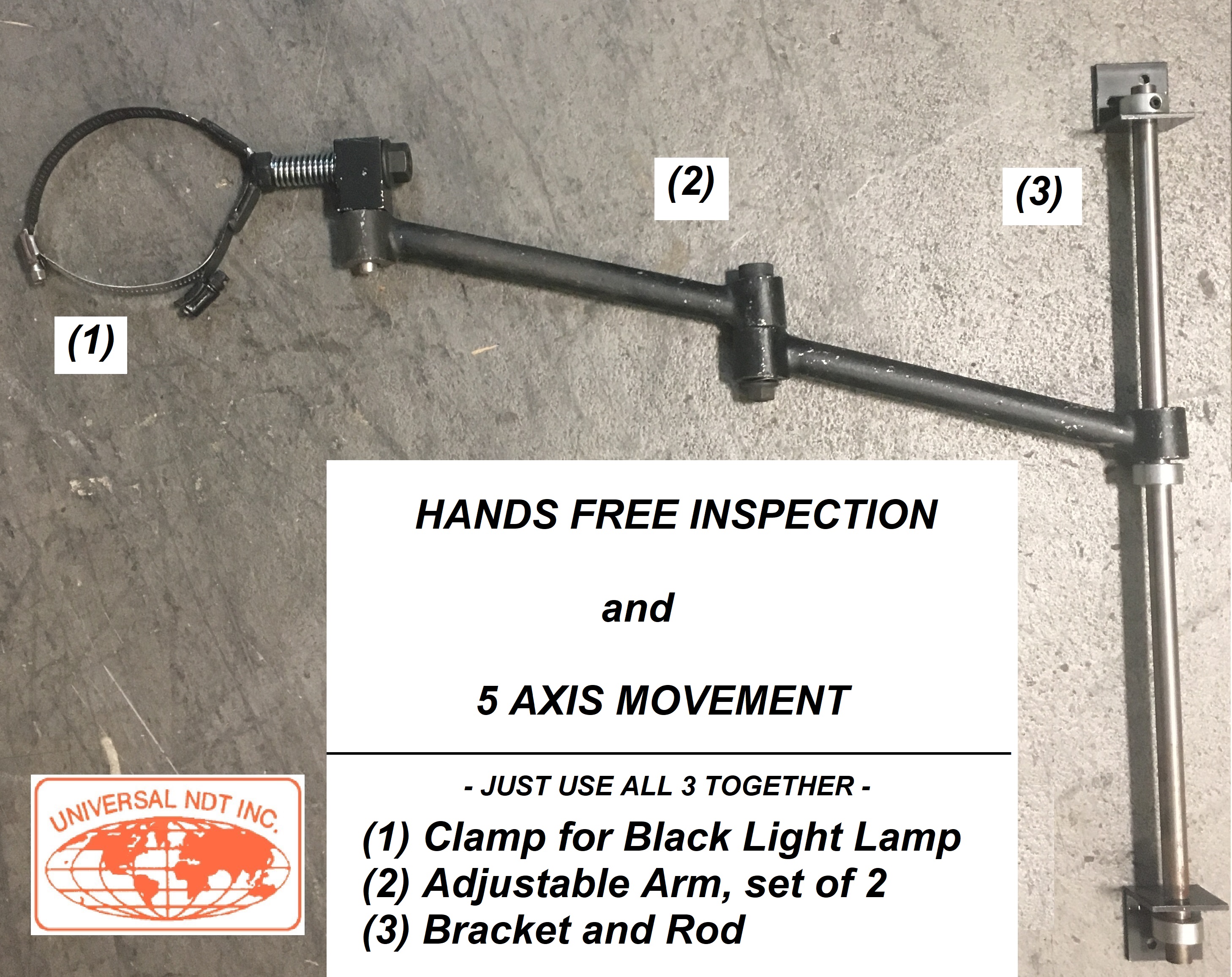

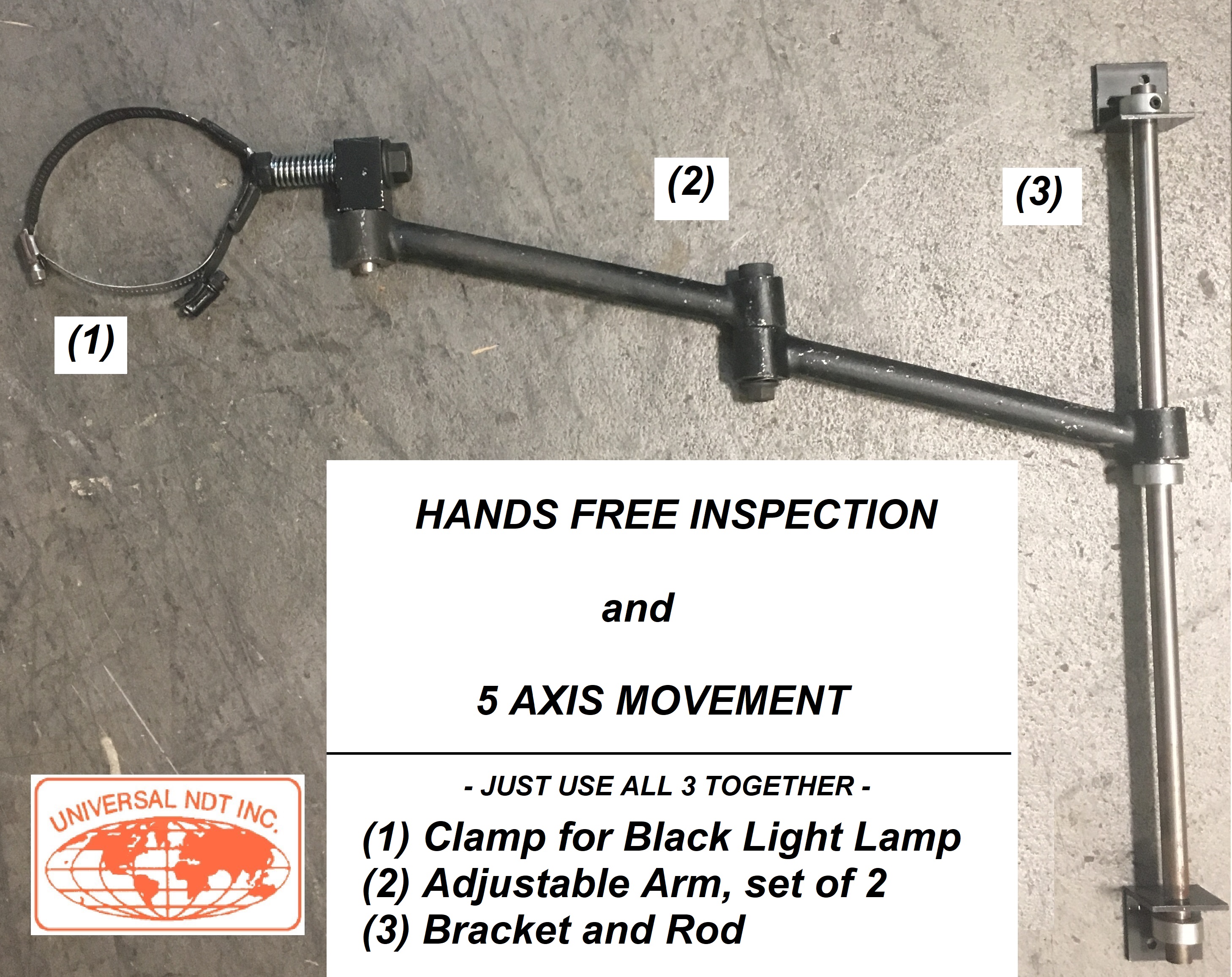

VISUAL INSPECTION (VT) & MEASURING DEVICES –

- Borescopes

- Calipers, Micrometers, Dial Indicators, Depth Gages, Height Gages

- Gage Blocks, Pin Gages, Shims, Pitch Gages, Feeler Gages

- Thread plugs, Ring Gages

- Comparator stands, Profile Projectors

- Magnifying Comparators, Magnifying Loupes

- Scales

|

|

|

CLEANING SYSTEMS -

- In-Line Plate Cleaning System

- Cleaning Tanks using Ultrasonic Transducers with Circulated, Heated, Solutions

|

|

![]() We also accept the "Government Card" for purchases

We also accept the "Government Card" for purchases